Screening machines CVT

Screening machines CVT

Reliability. tradition and modernization

VIBRATION SCREENING MACHINE RAPID

For screening granular and loose material, especially aggregates, gravel and ores in both dry and wet processes.

Traditional vibrating screening machines of Czech production with verified quality (used to be Svedala or Dragon).

BASIC DESCRIPTION:

- Circular movement via eccentric shaft mounted on SKF bearings which can compensate for uneven loading of the screening machine due to its construction

- Screens with inclined screen surface, which can be easily adjusted in the range of 14-22 degrees (standard is 18). They are either supplied with a supporting frame or they are suitable for being mounted on a supporting structure or suspended (smaller types).

- High performance, while maintaining sharpness of screening. Great resistance to wedging and sticking the screen.

- Self-supporting fixed mesh frames (replaceable) with an option of fitting wire, polyurethane. rubber or sheet metal screens with various mounting types (tensioned. modular. self-supporting)

- Robust screwed construction with high overload resistance during operation (use of Huck-bolt blind rivets at highly exposed points).

- They are characterized by easy maintenance as well as tensioning of the V-belt of the electric motor due to its swinging placement on the frame of the screening machine.

- All screening machines also include an input hopper lined with abrasion resistant HB 400 sheets (can be changed as required)

OTHER OPTIONS:

- Installation of effective dust covers or suction ca be a part of the delivery

- SKF automatic lubrication box can be installed

- Shower for the screen surface can be a part of the delivery

TYPES:

|

Designation

|

Screen area (m2) |

Number of

|

Weight (kg) |

Electric motor

|

|

CVT 75x250 |

1,88 |

1 |

1200 |

4 |

|

|

|

2 |

1340 |

4 |

|

|

|

3 |

1670 |

5,5 |

|

|

|

4 |

1840 |

5,5 |

|

CVT 100x300 |

3 |

1 |

1450 |

5,5 |

|

|

|

2 |

1650 |

5,5 |

|

|

|

3 |

2200 |

7,5 |

|

|

|

4 |

2420 |

7,5 |

|

CVT 125x350 |

4,38 |

1 |

1880 |

7,5 |

|

|

|

2 |

2220 |

7,5 |

|

|

|

3 |

3180 |

11 |

|

|

|

4 |

3550 |

11 |

|

CVT 150x400 |

6 |

1 |

2620 |

11 |

|

|

|

2 |

3930 |

11 |

|

|

|

3 |

4180 |

15 |

|

|

|

4 |

6790 |

15 |

|

CVT 150x500 |

7,5 |

1 |

3030 |

15 |

|

|

|

2 |

3520 |

15 |

|

|

|

3 |

5680 |

22 |

|

|

|

4 |

6160 |

22 |

|

CVT 150x650 |

9,75 |

1 |

3430 |

15 |

|

|

|

2 |

3930 |

15 |

|

|

|

3 |

5790 |

22 |

|

|

|

4 |

6790 |

22 |

|

CVT 175x500 |

8,75 |

1 |

4480 |

22 |

|

|

|

2 |

5180 |

22 |

|

|

|

3 |

7280 |

30 |

|

|

|

4 |

8780 |

30 |

|

CVT 200x500 |

10 |

1 |

5970 |

22 |

|

|

|

2 |

6880 |

22 |

|

|

|

3 |

9230 |

30 |

|

|

|

4 |

11260 |

30 |

|

CVT 200x600 |

12 |

1 |

6480 |

30 |

|

|

|

2 |

7770 |

30 |

|

|

|

3 |

10950 |

37 |

|

|

|

4 |

13260 |

37 |

|

CVT 250x600 |

15 |

1 |

8950 |

37 |

|

|

|

2 |

10420 |

37 |

|

|

|

3 |

13990 |

45 |

|

|

|

4 |

13990 |

45 |

|

CVT 250x700 |

17,5 |

1 |

10530 |

45 |

|

|

|

2 |

12320 |

45 |

|

|

|

3 |

16160 |

45 |

|

|

|

4 |

16160 |

45 |

Dimensions

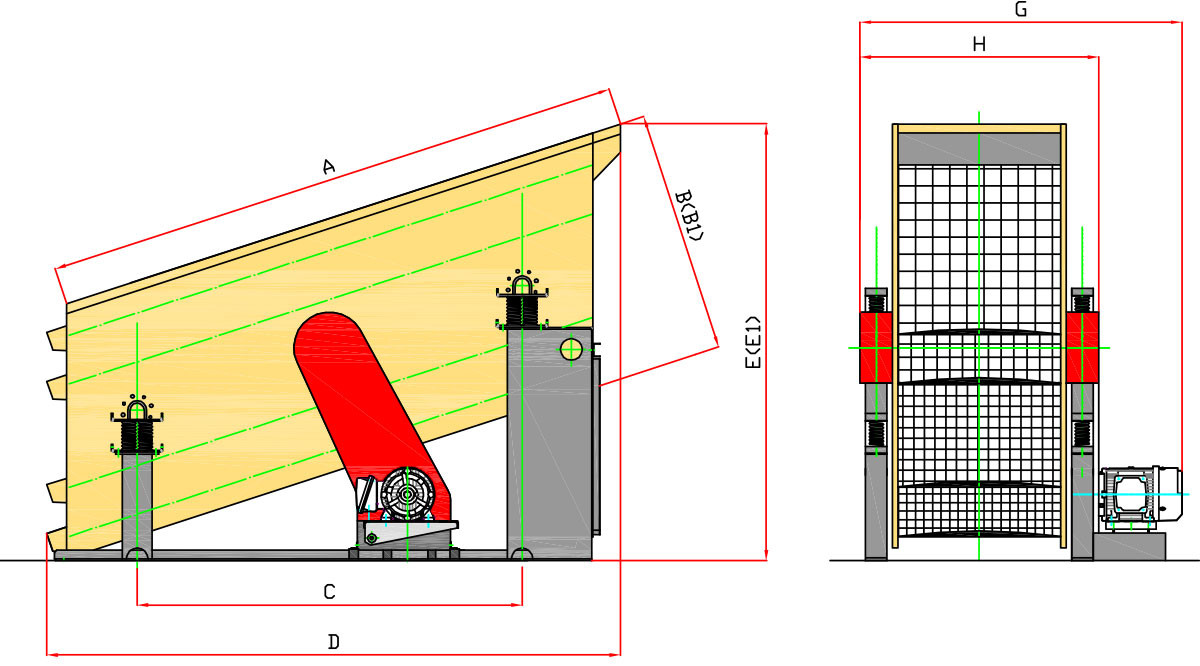

SCREENING MACHINES DIMENSIONS:

| Screening machine | A | B | B1 | C | D | E | E1 | G | H |

| CVT 75x250 | 2600 | 900 | 1500 | 1426 | 2648 | 1778 | 2398 | 1522 | 1145 |

| CVT 100x300 | 3325 | 965 | 1630 | 1902 | 2926 | 2024 | 2730 | 1772 | 1406 |

| CVT 125x350 | 3825 | 1030 | 1730 | 2378 | 3442 | 2256 | 2980 | 2026 | 1683 |

| CVT 150x400 | 4390 | 1100 | 1840 | 2853 | 3877 | 2395 | 3268 | 2276 | 1992 |

| CVT 150x500 | 5390 | 1140 | 1895 | 3804 | 4848 | 2850 | 3640 | 2600 | 2080 |

| CVT 150x650 | 6890 | 1145 | 2245 | 5231 | 6277 | 3369 | 4655 | 2600 | 2097,5 |

| CVT 175x500 | 5380 | 1470 | 2110 | 3804 | 4844 | 3332 | 3978 | 2840 | 2337,5 |

| CVT 200x500 | 5380 | 1470 | 2110 | 3804 | 4844 | 3332 | 3978 | 3100 | 2597,5 |

| CVT 200x600 | 6380 | 1540 | 2180 | 4755 | 5804 | 2659 | 4307 | 3100 | 2683 |

| CVT 250x600 | 6380 | 1665 |

|

4755 | 5804 | 3738 |

|

3604 | 3206 |

| CVT 250x600/3 | 6380 |

|

2350 | 4755 | 5804 |

|

4443 | 3604 | 3206 |

| CVT 250x700 | 7380 | 1850 |

|

5706 | 6754 | 4090 |

|

3604 | 3206 |

| CVT 250x700/3 | 7380 |

|

2350 | 5706 | 6754 |

|

4748 | 3604 | 3206 |

Dimensions of CVT product line screening machines include a hopper. They are given in mm.

Dimensions B and E are for screening machines with one up to two screens, B1 and E1 for screening machines with three up to four screens.

In connection with further development of the screening machines we reserve the right to change the above dimensions without prior notice.

All information given in the leaflet is of an informative character and is not contractually binding.